Making Your Job Easier, More Productive and Mmore Rewarding with 3D CAD

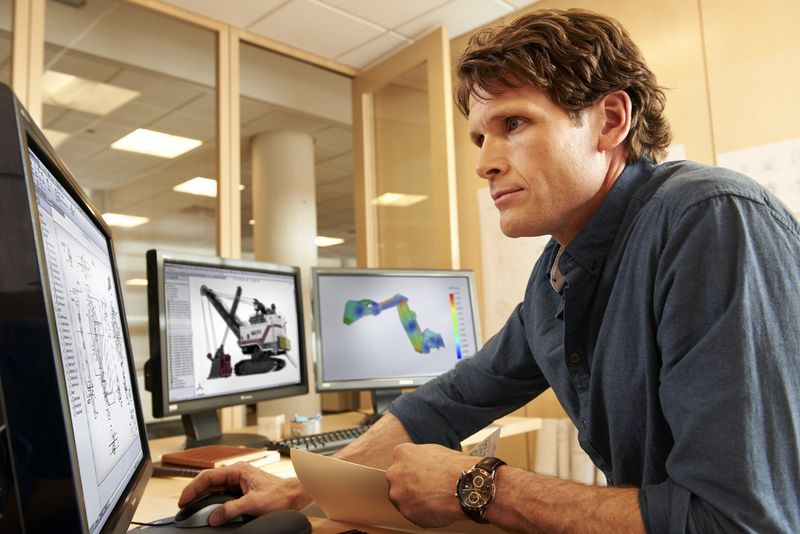

Transitioning to 3D design will liberate you from the repetitive tasks, wasted effort, and “busy work” that consume so much of your time in 2D and prevent you from doing what you love: designing.

Instead of focusing on producing drawings, updating drawing views, and checking drawing updates, 3D frees you to direct your focus more on the design, engineering, and manufacturing of products. This, in turn, will help you work more effectively with colleagues, customers, partners, vendors, and other departments in your company, and continue to innovate and grow as an engineer.

3D Helps You Do Your Job Better

When you can model product designs more efficiently, deliver product designs more accurately, and make design changes more quickly and easily, you’re doing a better job as an engineer.

However, that’s just the beginning of what 3D can do for you in terms of job performance. By providing complete design visualisation, improved design communication, and integrated specialised solutions, 3D will help you minimise manufacturing issues, enhance collaboration, improve product performance, and capitalise on opportunities for automation.

3D design lets you automatically check for interference’s and collisions within your assembly and locate misaligned holes, so they don’t show up on the production floor and cause unnecessary delays and costs. At least one 3D system (SOLIDWORKS) also enables you to evaluate the manufacturability of your designs, so you can assess whether or not your model needs to be modified to reduce the cost of machining, moulding, casting/forging, fabrication, and assembly operations.

Moving to 3D also enables you to leverage integrated design analysis tools, which allow you to simulate design behaviour to be simulated under the specific loads and boundary conditions of your product’s unique operating environment. With this information, you can modify designs to reduce stresses that avert field failures, iterate on designs to reduce weight to boost performance, or cut costs by reducing material while maintaining performance.

With 3D, you can also automate important processes, such as automatically generating bill of material (BOM) information directly from your model with no need for manual entry or checking. You can tap the power of design configurations to automatically create designs for product families or similar product models—with slight variations in length, size, weight, capacity, etc.—from your initial design. You can even leverage 3D CAD data to automate the creation of assembly instructions

and product documentation.

3D Helps You Work More Effectively with Others

The ease of design visualisation and communication in 3D will enable you to work more closely and effectively with colleagues, customers, partners, suppliers, vendors, and other departments within your company. You can quickly and easily create animations and photo-realistic renderings to illustrate new design concepts; take advantage of applications like SOLIDWORKS eDrawings® to email compact 2D and 3D models to customers and partners for review; or import and export data in different CAD file formats.

The flexibility to create various types of 3D CAD imagery and data—backed by a 3D model’s inherent engineering, dimension, geometry, and material information—is critically important because 3D is becoming the design standard for most major suppliers and vendors. Many of these companies no longer accept 2D files, making 3D data increasingly valuable when working with external partners.

3D data will also help you more effectively support upstream and downstream uses and processes within your company, for which 2D drawings can prove problematic. With 3D, you can create proposals that are more compelling and dynamic; support quoting and estimating functions with

both 2D and 3D data for improved clarity; automate the creation of assembly instructions and product documentation; streamline the hand-off to manufacturing by running CAM operations directly from your 3D model; and give sales/marketing personnel the 3D imagery that they need to make product introductions successful.

3D Helps You Innovate and Grow as an Engineer

Moving to 3D will also help you keep growing and innovating as an engineer, continually improving your effectiveness, increasing your contributions, and heightening your impact in product development and beyond. 3D lets you focus on the design rather than drawing requirements so you can reach your creative potential. It also enables you to increase your manufacturing process know how and fully understand how product development affects other functions in your company through the extended use of 3D design data.

Your maturation as an engineering professional is extremely important for your organisation, because it will prepare you to take advantage of new approaches, methodologies, and technologies that keep your company competitive and successful. For example, while 2D engineering drawings have been the basis for manufacturing for many years, a new model-based definition (MBD) approach to production is emerging.

With MBD, 2D drawings are replaced with 3D solid models, with all of the information contained on an engineering print—such as geometric dimensioning and tolerating, component-level materials, assembly-level BOMs, and engineering configurations contained within the 3D data. MBD holds great promise for making manufacturing setup as easy as pressing a button, similar to sending a model to a 3D printer. With 3D, you will be ready to help your organisation capitalise on innovative methods like MBD, enabling both you and your company to continue to grow and prosper.